Criplon Textiles, LLC is a Sydney-based manufacturer of advanced technical textiles engineered for demanding industrial and performance applications. Our fabrics are designed with function at the core—delivering strength, durability, environmental resistance, and specialized performance where conventional textiles fall short.

Criplon’s technical textile offerings include knit and warp-knit fabrics that can be customized with properties such as antibacterial performance, anti-static and chemical resistance, flame retardancy, UV resistance, and high abrasion resistance. Each material is engineered to meet specific operational requirements across industrial environments.

Our technical textiles are used across a wide range of industries including healthcare and medical applications, automotive and transportation, industrial filtration and substrates, protective and safety textiles, and recreational and sporting equipment.

Technical textiles are purpose-built solutions designed to enhance product performance, protect assets and personnel, and improve operational reliability. By focusing on functionality over aesthetics, these materials help businesses meet safety, durability, and compliance requirements.

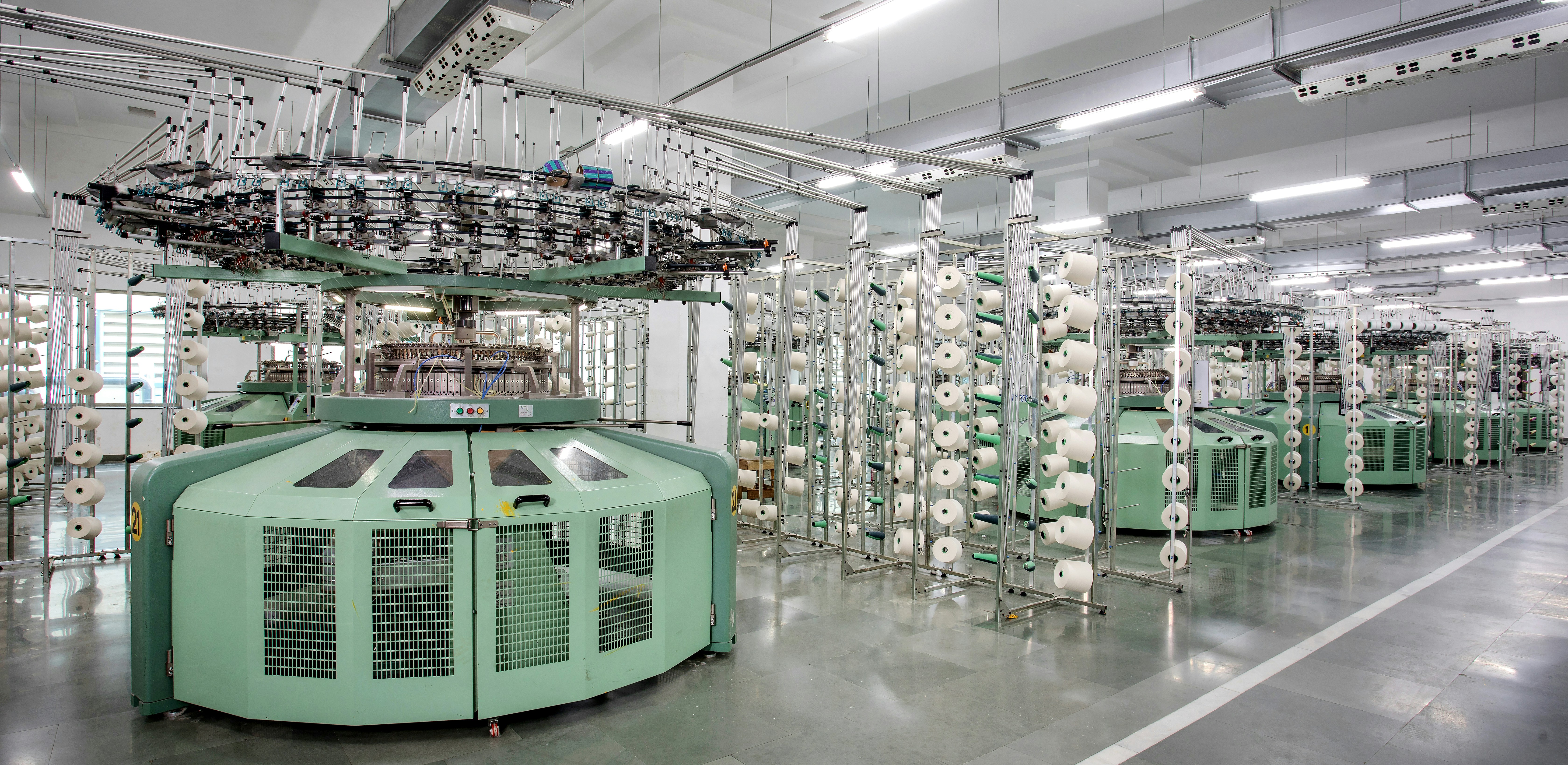

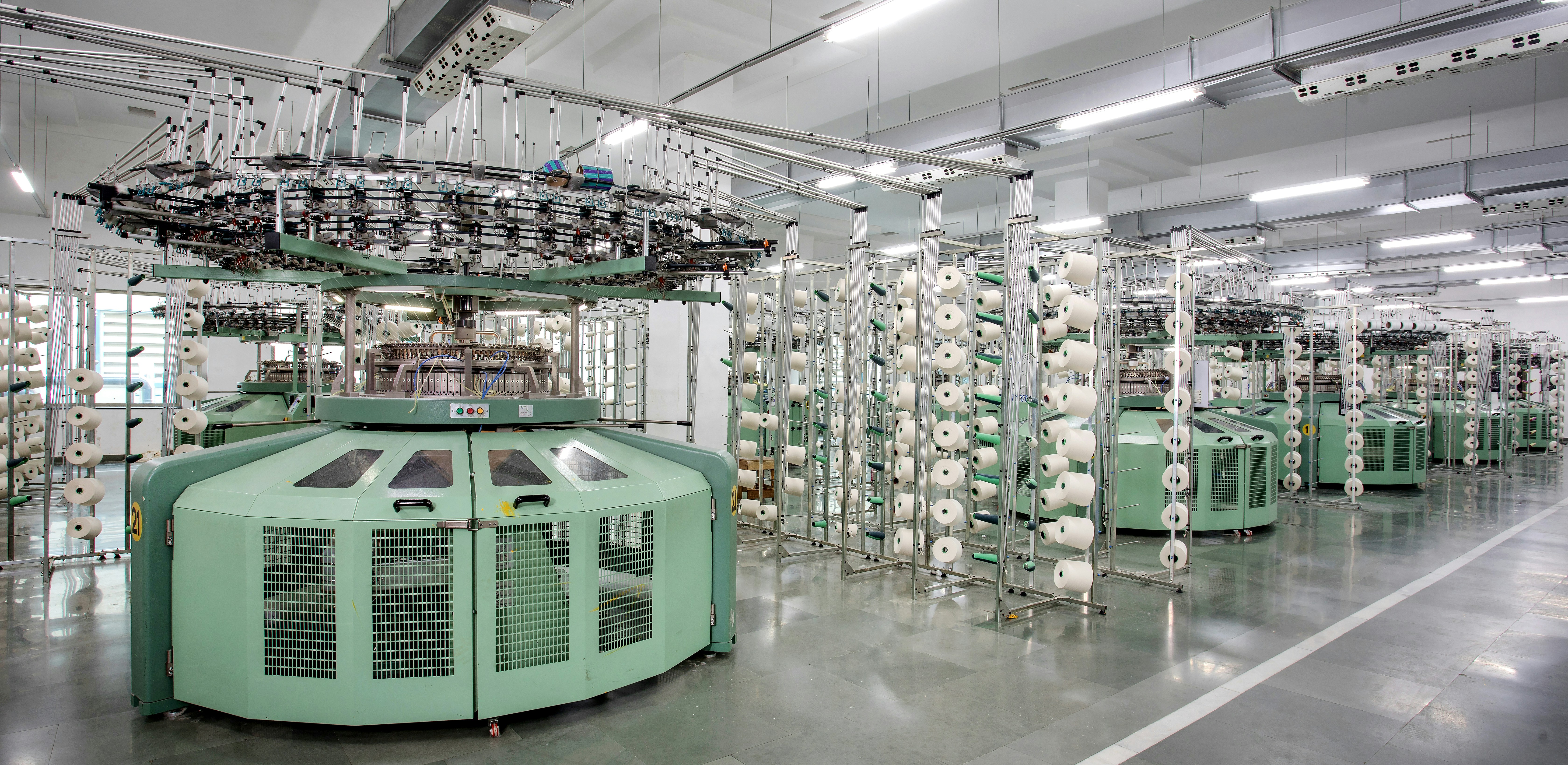

With over four decades of manufacturing experience, Criplon Textiles combines advanced warp-knitting technology with custom development capabilities. Our team works closely with customers to deliver technical textile solutions tailored to specific industry needs.

Engage with Criplon Textiles to develop technical textile solutions engineered to meet your specific performance, compliance, and operational requirements.

Speak with Our Technical TeamPrivacy | Sitemap | Terms & Conditions | Catalog Index